We are the Backbone of Transfer Solutions

We are the Backbone of Transfer Solutions

We are the Backbone of Transfer Solutions

We are the Backbone of Transfer Solutions

We are the provider of products and

services that meet the needs and

challenges of your facility.

We are the solution to the never-ending and ever-growing technical problems and needs of facilities.

We offer solutions that add value to production, are environmentally friendly, and result in cost savings

Our Products

Metal cased centrifugal pumps are more resistant in situations where liquids are exposed to high temperature, pressure, and chemical effects. Additionally, metal cased centrifugal pumps generally have higher flow rates and higher pressures.

Plastic cased centrifugal pumps are commonly used in heavy industrial applications, chemical and food industries. The plastic casing is more resistant to chemical substances and is lighter in weight. They offer advantages such as low cost, low maintenance requirements, and quiet operation.

Air-operated double diaphragm pumps, which utilize air pressure as the driving force to move liquids, are a type of pump used for liquid transfer.

The pump features two diaphragms, and each diaphragm seals off a liquid chamber to facilitate the movement of the liquid. The air supply compresses one diaphragm while expanding the other, transferring the liquid from one side to the other. This process is repeated with the movement of the diaphragms, ensuring a smooth flow of the liquid.

Air-operated double diaphragm pumps are used in chemical processes, food processing, pharmaceutical industry, and various other industries. They offer advantages such as low maintenance requirements, high reliability, and cost-effectiveness. Additionally, they do not require a separate valve to stop the flow of liquids and prevent liquid contamination.

Pumps used for the transfer of liquefied petroleum gas (LPG) are typically designed as multi-stage pumps to ensure high efficiency and reliability.

A multi-stage pump is a pump that consists of a series of stages or steps. Each stage increases the pressure of the liquid and passes it to the next stage. Therefore, a multi-stage pump is ideal for applications that require high pressure.

LPG pumps are used for high-volume transfer operations. These pumps feature high flow rates, high pressures, low vibration, and low noise levels. LPG pumps are commonly used in places where the liquid needs to be transferred at high pressures, such as LPG distribution stations, tankers, and industrial applications.

Mechanical seals are components used to connect machine parts and provide sealing. They are designed to prevent the leakage of oil, water, chemicals, or gases to the outside. Mechanical seals typically consist of rotating seals around moving shafts, creating a tight seal between mating surfaces.

Couplings are components that transmit motion from one machine part to another. They connect devices such as motors and pumps, transferring motion between them. Couplings provide a strong connection between machine parts and are used for power and motion transmission. They also help reduce shocks and vibrations between machine parts.

Mechanical seals and couplings have a wide range of applications in industrial settings. They are used in industries such as energy, chemical processing, food processing, mining, construction, and many others. These components ensure proper functioning of machine parts and contribute to a safe working environment.

Dosing pumps are designed to transfer liquids or chemicals in a measured and controlled manner. These pumps are commonly used in industrial applications that require the transfer of liquids in small quantities and at specific rates. Dosing pumps are particularly used in industries where accurate and precise dosing of chemicals and liquids is essential, such as pharmaceuticals, food processing, and water treatment.

Peristaltic hose pumps operate by transferring liquids through hoses. The hoses are compressed through peristaltic movements, allowing the liquid to progress from one end to the other. These pumps are widely used in industries where the liquids are chemical, toxic, or corrosive in nature. Additionally, peristaltic hose pumps offer the advantage of operating in hygienic conditions by creating a completely enclosed system, preventing liquid contamination.

Gear pumps enable the transfer of liquids through the rotation of gears. These pumps are used in low and medium-pressure applications. Gear pumps are cost-effective and easy to use. Additionally, due to their typically higher speeds, gear pumps have high flow rates.

Screw pumps transfer liquids through the rotation of screws. These pumps offer lower noise levels and lower vibrations compared to other pumps, making them a less abrasive option. Screw pumps are commonly used in industries such as food processing, chemical, and petrochemical, especially for transferring high-viscosity liquids.

Drum pumps are designed to transfer liquids from drums. These pumps operate using air or electric motors and extract the liquid from the drum for dispensing. Drum pumps are commonly used in the chemical, petroleum, and food industries.

IBC pumps, on the other hand, are used to transfer liquids from larger capacity IBCs (Intermediate Bulk Containers). These pumps operate using electric or air motors and extract the liquid from the top connection points of the IBC for dispensing. IBC pumps are typically used in the chemical, petrochemical, and food industries.

Our Services

Sales Services

- Procurement of all types of pumps and spare parts

- Supply of seals

- Supply of couplings

- Supply of lubrication equipment

Engineering Services

- Pump selection

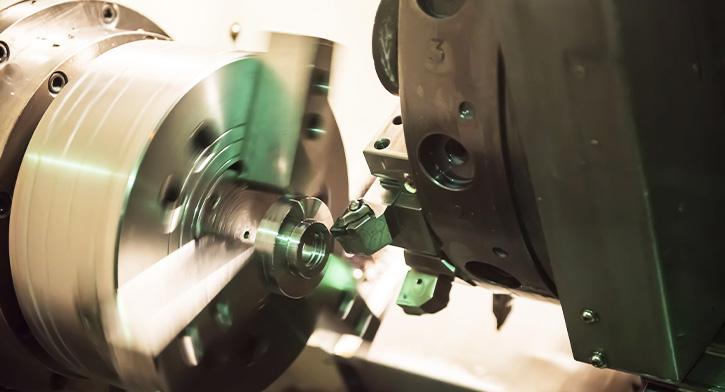

- Pipe manufacturing and installation

- Technical support

Service & Maintenance

- Pump maintenance and repair

- Commissioning and reporting

- Mechanical seal conversions

Predictive Maintenance

- Laser coupling alignment

- Vibration measurement

- Thermal temperature measurement

- Oil analysis and reporting

01 01

High Quality

Omurga Machinery possesses a strong customer service ethic and strives for excellence because we understand the critical importance of our equipment to our customers' production. Our customers trust us to provide spare parts and technical support. From the initial meeting to after-sales support, we aim to deliver unparalleled service.

02 02

Comprehensive Expertise

Established in 2015, Omurga Machinery is one of Turkey's leading manufacturers of fluid transfer equipment. Our extensive experience in the field enables us to provide solutions for both simple and complex pump and sealing applications.

03 03

Diversity in Industries and Sectors

Our machines are flexible and adaptable, making them suitable for a wide range of applications in various industries and sectors.

For your brand

We Guide

the Fluid Transfer

Omurga Generates Solutionsr

Omurga Generates Solutions

Omurga Generates Solutions

Omurga Generates Solutions

News

Looking for collaboration?

OMURGA MAKİNA

Babacan Sanayi Sitesi Sultan Orhan Mahallesi 1185 Sokak NO:8 /B GEBZE KOCAELİ

Send us a message

CONTACT FORM